A2L Refrigerant Roadmap

Prepare for the refrigerant transition with our comprehensive A2L Refrigerant Roadmap. Learn about phase-down timelines, new refrigerant options, storage guidelines, and tool updates for multifamily HVAC systems.

The residential HVAC industry is in the process of a major shift. R-410A is being phased down. Deadlines have been set for the manufacture and sale of R-410A compatible equipment, and the amount of R-410A refrigerant being produced has already been significantly decreased. These facts have left multifamily owners and operators with many questions, including:

- What is happening to R-410A?

- What are the reduction deadlines for refrigerant productions?

- Can I still buy R-410A equipment?

- Will my supplier run out of the R-410A equipment and parts I need?

- What will replace R-410A in the market?

Chadwell Supply is fielding questions from our industry partners and working with HVAC experts to create a Refrigerant Transition Library that will answer all your questions and arm you with the information you need to make the best decisions for your properties.

Get answers to the most common questions about A2L refrigerants:

Why are HFC refrigerants like R-410A being phased down?

For decades now, regulations impacting the residential and commercial HVAC market have attempted to develop standards that balance concerns related to performance and environmental responsibility. Where and when to draw that line remains an ongoing debate. Legislative bodies around the world have passed regulations that describe safe and proper use standards for refrigerants known to have an impact on the environment.

Decades ago, the challenge was limiting refrigerants thought to have a depleting effect on the ozone layer. Hydrofluorocarbons (HFCs) were developed and manufactured as replacements for ozone-depleting substances (Source: epa.gov).

- These efforts were largely successful, as adoption of refrigerants like R-410A did have a noticeable environmental impact.

- Further study determined that HFCs were also potent greenhouse gases.

- The environmental impact of an HFC is determined by measuring the Global Warming Potential (GWP).

- This formula compares the environmental impact of CO2 with other greenhouse gases.

- CO2, has a GWP of 1.

- One kilogram of a gas with a 700 GWP score has an environmental impact that is 700 times stronger than one kilogram of CO2.

Regulators determined that the residential and commercial HVAC market should shift away from high-GWP refrigerants and use alternatives that have much less global warming potential.

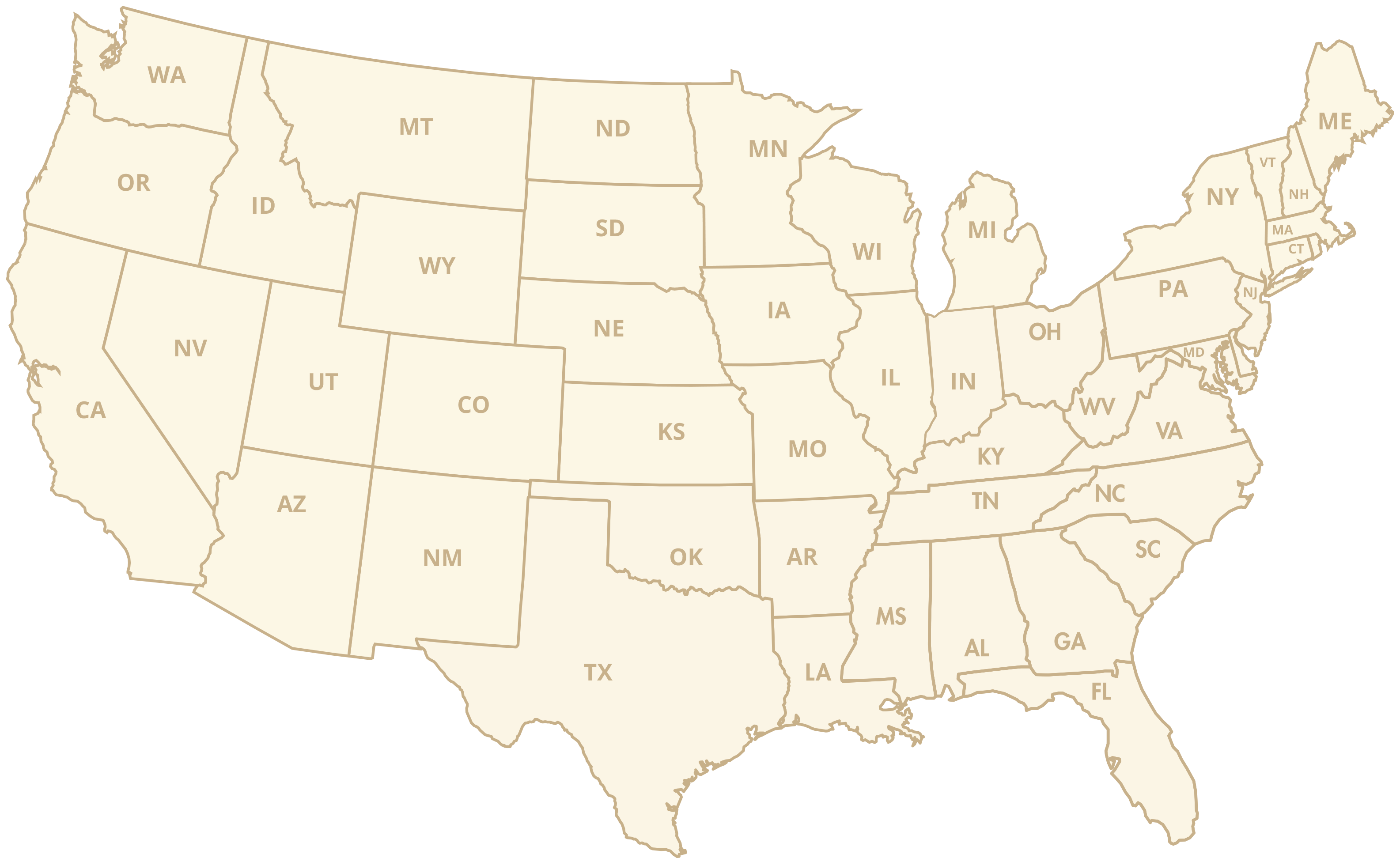

Review Your Building Codes

This AHRI interactive Map indicates state and local building codes related to A2L refrigerants

How is the United States refrigerant market being impacted?

The United States Environmental Protection Agency (EPA) has enacted new regulations limiting certain refrigerants. The AIM Act authorizes the EPA to reduce the production of hydrofluorocarbon (HFC) refrigerants that have high Global Warming Potential (GWP).

- Residential refrigerants with a GWP rating above 700 must be phased down.

- HFC refrigerants like R-410A are included in this phase down.

- This phase down will lead to a shift to lower-GWP refrigerants.

- This transition will have a significant impact on HVAC repair and maintenance in the multifamily industry.

When is the R-410 phase down happening?

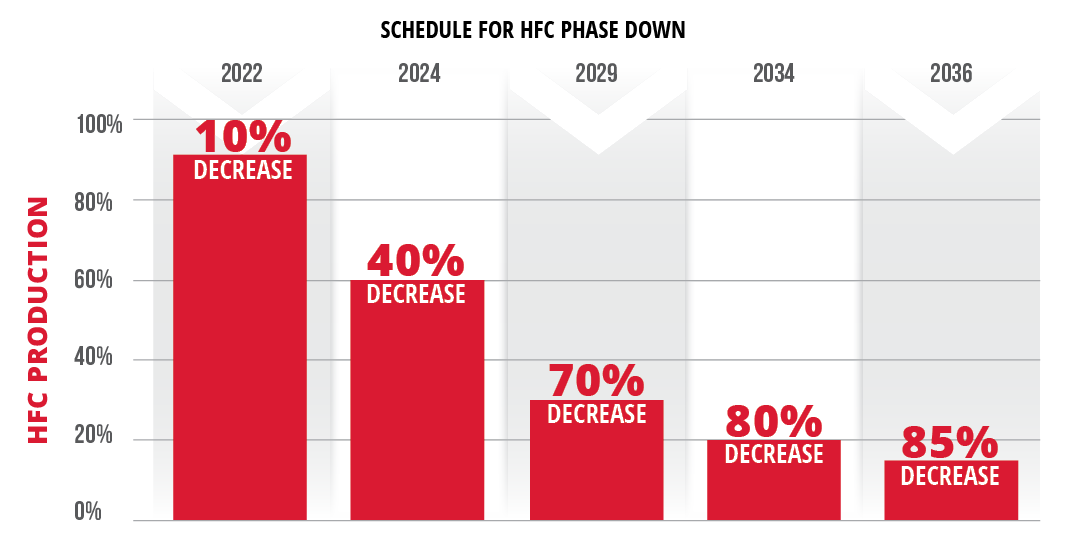

Beginning in 2022, high GWP refrigerants like R-410A are being gradually phased down.

In January 2024, HFC refrigerant was phased down by 40 percent. This was the first of two large cuts.

The next big 30% cut will come in 2029 with two smaller R-410A reductions in 2034 (10%) and 2036 (5%).

By 2036, the production of HFC refrigerants will have been reduced to 15 percent of baseline levels. While this is a phase DOWN, not a phase OUT, the market has already begun to see a gradual rise in the cost of R-410A refrigerant. This trend is expected to continue as the phase down increases.

What about equipment that uses R-410A?

These regulations also establish deadlines for the manufacture, sale, and installation of A2L equipment.

- December 31, 2024 – HVAC Equipment compatible with R-410A refrigerants can no longer be manufactured after this date.

- December 31, 2025 – R-410A equipment can no longer be sold or installed after this date.

A2L refrigerants: Increased efficiency, reduced environmental impact

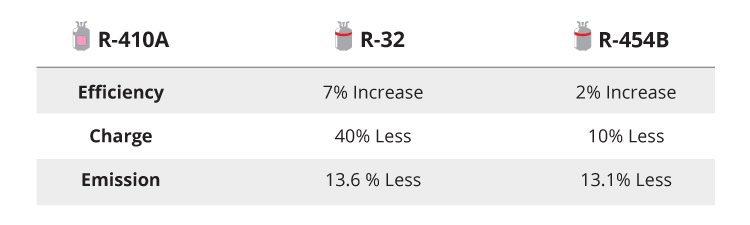

While high-GWP refrigerants are not being phased out completely, the phased-down production will be replaced by low-GWP A2L refrigerants including R-32 and R-454B.

R-32 and R-454B were both developed in anticipation of growing international concern over the global warming potential (GWP) of HFC refrigerants like R-410A.

When compared to high-GWP refrigerants like R-410A, both A2L rated refrigerants, R-32 and R-454B, are more efficient and operate with less refrigerant charge and lower emissions.

Are A2L refrigerants dangerous?

Care should always be taken when working with any refrigerants. When handled correctly, using the proper tools, A2L refrigerants are safe and reliable. Most experienced maintenance technicians will feel very comfortable working with the new refrigerants as the tools and pressures are very similar.

What about flammability?

Flammability designations are determined by the American Society of Heating, Refrigerating, and Air Conditioning Engineers (ASHRAE). To measure flammability, ASHRAE uses the ASTM E-681 test.

- A1 rated refrigerants such as R-410A have no flame propagation.

- A3 rated refrigerants such as R-290 (propane) are highly flammable.

- A2L is a new, special designation describing refrigerants that are difficult to ignite and have a low burning velocity.

Storing A2L refrigerants

Multifamily operators should evaluate their properties to determine if they are compliant with new regulations related to the storage of A2L refrigerants. Factors to consider include maximum quantities, shelving material and spacing, temperature in the storage facility, signage, documentation, and mitigation systems, including fire suppression.

- Occupational Safety and Health Administration (OSHA) safety storage guidelines require flammable refrigerant cylinders:

- Be stored in a secure, ventilated enclosure

- Should be stored in the upright position, so the pressure relief device is in contact with the vapor space of the cylinder

- Cannot be stored in confined spaces, containers, or lockers

- The National Fire Protection Association (NFPA) has established specific codes for the proper storage of A2L refrigerants. In general, facilities must have:

- A valid permit from a local fire code official

- No open flames, high temperature devices, or combustion appliances in the storage area

- Visible hazard identification signage

- A hazardous materials management plan and inventory statement available for review

- Safety data sheets for each type of gas stored onsite

- Standards and codes limit the storage of flammable refrigerants to a specific weight per control area.

- Management teams should check with their local inspectors to be sure they are compliant.

What about mitigation systems?

Mitigation systems are required to include active sensors when flammable refrigerants are present. Additional mitigation options may include:

- Permanent ventilation

- Constant airflow

- Sprinkler or fire suppression systems

However, there are no “one size fits all” mitigation solutions. Multifamily operators should consult their local codes to determine which kind of mitigation system is suggested or required for storing A2L refrigerants.

What will A2L tanks look like - are they different from R-410A?

R-22 and R-410A refrigerant tanks were easy to spot due to their distinctive colors—green for R-22 and pink for R-410A. A2L refrigerant tanks will also have a distinctive design. However, all A2L refrigerants will have the same distinctive design, so technicians will have to be extra careful to make sure they order, tag, and use the correct refrigerant.

A2L refrigerant tanks such as R-32 and R-454B will be white or gray with a red band at the top. The actual type of refrigerant will be stamped on the side of the tank.

A2L refrigerant tanks will also have a pressure release valve, rather than a rupture disc, for increased safety.

As an added safety feature, A2L tanks will have reverse (left-handed) threads on the connectors

A2L Recovery Tanks

A1 (R-410A) and A2L (R-32 and R-454B) recovery tanks are both gray with a yellow top. A2L cylinders will also have a red stripe and will have reverse (left-handed) threaded connections.

IMPORTANT: All refrigerant types and cylinders MUST be clearly labeled. Never mix refrigerants.

A2L Tools - Will my current tools work with the new refrigerants?

Some tools used to install and maintain refrigerant equipment will need to be updated to work on A2L equipment safely. Others will not.

- Tools that DO NOT touch the refrigerant circuit are generally compatible with both A1 and A2L systems.

- Tools that DO touch the refrigerant circuit should be non-arcing and non-sparking.

- Non-electric hand tools should work with both A1 and A2L systems.

Check out this full list of A2L compatible tools.

A2L training - Is additional certification required?

EPA608 certification courses offer training on the storage and use of flammable refrigerants. There is currently no additional federal certification required to work with A2L refrigerants. Supplemental safety training is encouraged to ensure that maintenance teams are competent and comfortable working with this new category of refrigerant.

Stay up to date with the latest MRO industry news and take a deep dive into important issues affecting multifamily property maintenance and operations.

Review Your Building Codes

This AHRI interactive Map indicates state and local building codes related to A2L refrigerants.