Foolproof Furnace Maintenance

Take good care of a furnace, and it will work efficiently and cost-effectively for many years. Learn how to properly maintain a furnace as well as how each step contributes to the overall health and longevity of the unit.

A well-maintained furnace should last a decade, maybe two. For multifamily communities, regular maintenance is the single most important factor in getting the most out of every furnace on a property. Not only will annual furnace maintenance cut down on emergency calls, but annual furnace checkups will also identify small or potential issues before they become big problems.

When it comes to furnace maintenance in a multifamily community, how much is enough, especially when the maintenance team is balancing all the other necessary work on the property? Every furnace should be serviced at least once each year. This annual maintenance check should include:

- A visual inspection of the unit

- Cleaning or replacing air filters

- Checking the burner or heat exchanger

- Testing switches and electrical connections

- Ensuring proper furnace operation (heating, current flow, venting)

To help maintenance teams keep their furnaces protected and working properly, our furnace experts put together an easy-to-follow plan that explains what to do and why it’s an important factor in prolonging the life of every furnace on the property.

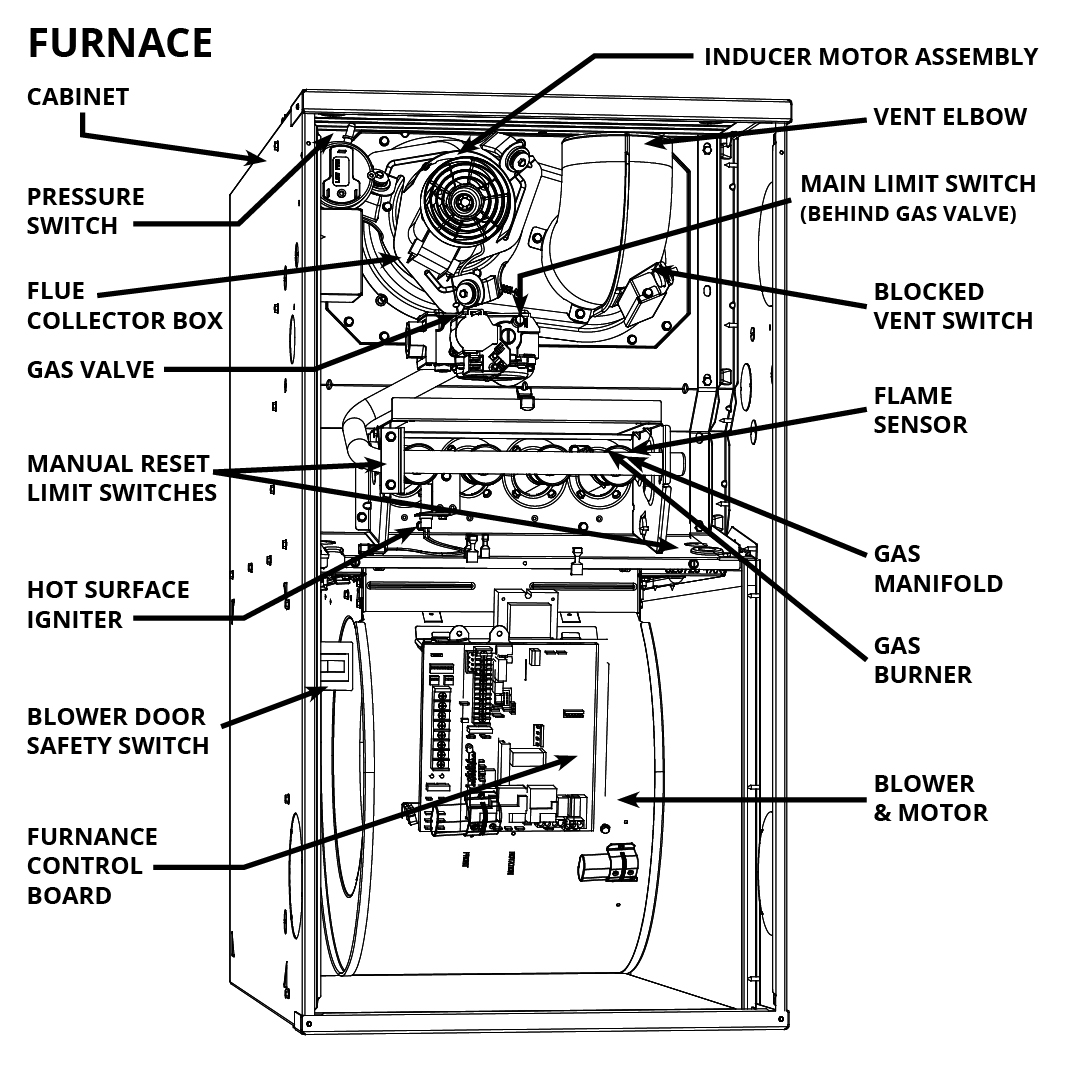

Key Furnace Components Include

- Cabinet

- Inducer Motor

- Pressure Switch

- Flue Collector

- Gas Valve

- Limit Switches

- Hot Surface Igniter

- Blower Safety Switch

- Furnace Control Board

- Blower and Motor

- Burner Assembly

- Gas Manifold

- Flame Sensor (Rod)

- Blocked Vent Switch

- Main Limit Switch

- Vent (elbow to duct)

Furnace Maintenance Checklist

NOTE: This maintenance checklist applies to 80% gas furnaces.

Annual furnace maintenance is a two-step process. First, check that all components are clean and undamaged. Then, run the furnace to test its function and measure key indicators of system health.

- Correct voltage should be between 92 and 97 volts

- Reversed polarity will read about 150v

- Moisture and debris on the plate will not allow the flame to continue from burner to burner.

- Damage to burner plates or too much of a pilot gap will cause the flame to fail to light all burners, limiting furnace function.

- If damaged, the ignitor may not spark.

- Ohm check for infinite resistance.

- Check for condensation where the heat exchanger connects with the vent pipe.

- Condensation is a sign of poor system performance.

- Wiring is clean and tight

- Tubing connected with the pressure switch is clean, pliable, and not cracked

- Current travels down the rod to indicate a flame.

- A dirty or damaged rectifier may cause a signal fault.

- If a rectifier is touching the chassis of the furnace this will cause an error code.

- Damage to ductwork will reduce the furnace’s natural draft, reducing efficiency.

- Moisture (condensation) in the flue is an indication of poor system performance.

Once the furnace component check is complete, run the system to ensure everything is operating properly. Check the flame current, pressures, and temperature rise (see below).

Testing Temperature Rise

Temperature rise is the difference in the air temperature entering the furnace (return) and the air temperature leaving the furnace to warm the living space (supply). Temperature rise is a very important indicator of overall furnace health. Maintaining proper rise will prevent short cycling and tripping the high limit. To measure a furnace’s temperature rise:

- Measure and record the return air temperature

- Measure and record the supply air temperature

- Subtract the return temp from the supply temp

- The difference is the temperature rise

Check the output against the manufacturer’s acceptable range for that unit, which will be noted on the furnace’s rating (data) plate. If the temperature rise is:

Too High? The air may be flowing too slowly, try:

- Raising the fan speed

- Lessening static pressure

- Decreasing gas pressure

- IMPORTANT: Pressure norms are different for natural gas and liquid propane, these will be noted on the rating (data) plate

Too low? The air may be flowing too quickly, try:

- Lowering fan speed

- Increasing gas pressure

- Adjusting duct static pressure

Efficiency Check

Adequate ventilation is necessary for proper furnace operation. Complete your furnace maintenance check with a visual review of the furnace room door. Door louvers should be open, clean, and free of obstructions that might impede air flow.

Cleaning Burners

Use a wire brush. Carefully sweep across the burners. Do not open the pilots too wide. Vacuum or blow out to complete cleaning.

DO NOT wash burners. Water droplets will deflect, block, or reroute gas away from heat exchanger.

Cleaning Sensing Rods

Always use steel wool (Item #353018) or scouring pads (Item #353110) to clean flame sensing rods and spark ignitors in gas furnaces.

Never use sand cloth or sandpaper. This can cause the sensor to fail prematurely due to the silica sand adhering to the flame sensor.