Brothers SEER2 Troubleshooting

The Brothers 14.3 SEER2 condenser is smaller, tougher, and stronger. It's clear diagnostic lights allow for fast, easy troubleshooting.

New product features of this condenser meet or exceed current SEER2 regulations while protecting the compressor and delivering a quieter, more efficient, and easier to maintain condenser.

It is important to know:

- The main control board is a DC inverter, to achieve the 14.3 SEER2 rating.

- The boards are installed in both the straight cool and heat pump

- Designed to protect against catastrophic failure.

- High and low-pressure switches help protect the unit.

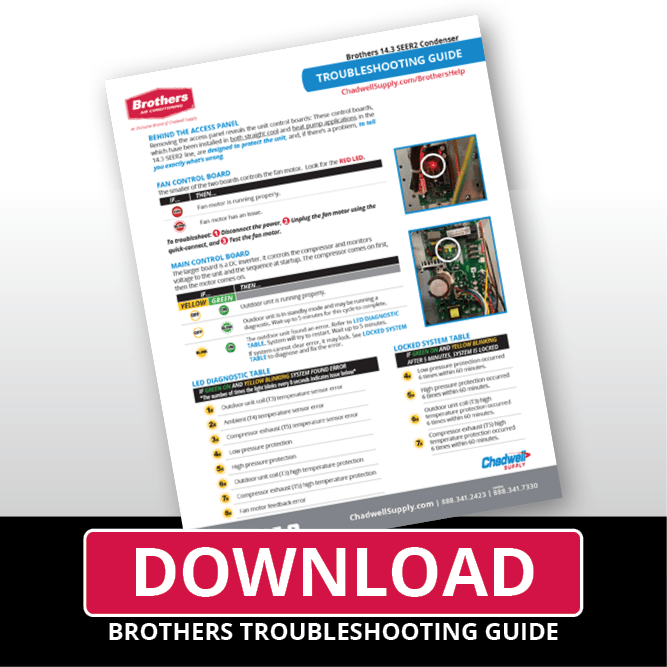

Behind the Access Panel

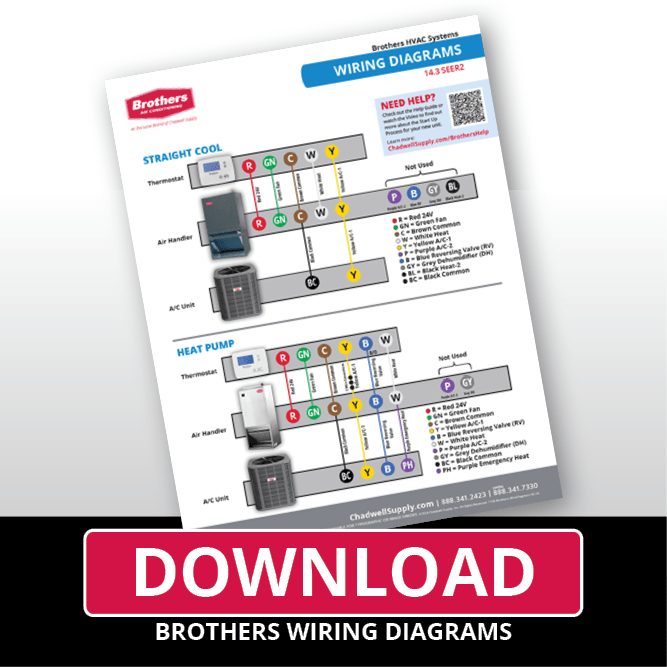

Removing the access panel of the Brothers 14.3 SEER2 condenser reveals the unit control boards. These control boards have been installed in both straight cool and heat pump applications. They are designed to protect the unit, and, if there’s a problem, to tell you exactly what’s wrong.

It is important to understand the different codes you may see. Kee this troubleshooting guide handy.

Fan Control Board

The smaller of the two boards controls the fan motor. Look for the RED LED.

| IF... | THEN... |

|---|---|

| Fan motor is running properly. | |

| Fan motor has an issue. |

To troubleshoot:

- Disconnect the power.

- Unplug the fan motor using the quick-connect.

- Test the fan motor.

Main Control Board

The larger board is a DC inverter. It controls the compressor and monitors voltage to the unit and the sequence at startup. The compressor comes on first, then the motor comes on.

| IF... | THEN..... | |

|---|---|---|

| YELLOW | GREEN | |

| Outdoor unit is running properly. | ||

| Outdoor unit is in standby mode and may be running a diagnostic. Wait up to five minutes for this cycle to complete. | ||

|

|

|

The outdoor unit found an error. Refer to LED DIAGNOSTIC TABLE. System will try to restart. Wait up to five minutes. If system cannot clear error, it may lock. See LOCKED SYSTEM TABLE to diagnose and fix the error. |

LED Diagnostic Table

|

IF GREEN ON AND YELLOW BLINKING SYSTEM FOUND ERROR *The number of times the light blinks every 8 seconds indicates the issue below.* |

|

|---|---|

|

Outdoor unit coil (T3) temperature sensor error. |

|

| Ambient (T4) temperature sensor error. | |

|

Compressor exhaust (T5) temperature sensor error. |

|

| Low pressure protection. | |

|

High pressure protection. |

|

| Outdoor unit coil (T3) high temperature protection. | |

|

Compressor exhaust (T5) high temperature protection. |

|

| Fan motor feedback error. | |

| Fan motor feedback error occurred 3 times within 20 minutes. | |

Locked System Table

|

IF GREEN ON AND YELLOW BLINKING SYSTEM AFTER 5 MINUTES, SYSTEM IS LOCKED *The number of times the light blinks every 8 seconds indicates the issue below.* |

|

|---|---|

|

Low pressure protection occurred 6 times within 60 minutes. |

|

|

High pressure protection occurred 6 times within 60 minutes. |

|

| Outdoor unit coil (T3) high temperature protection occurred 6 times within 60 minutes. | |

|

Compressor exhaust (T5) high temperature protection occurred 6 times within 60 minutes. |

|

|

Temperature sensor error. |

|

If the GREEN Light is Still Blinking, What's Next?

While the unit is in standby mode (GREEN LED blinking), the unit is either:

- waiting for a signal from the thermostat, or

- if you have recently changed the termperature, then it is processing.

Wait up to five minutes for the unit to come back on (STEADY GREEN) or display a fault light (BLINKING YELLOW). Do not change the thermostat until the unit starts or shows a fault.

If you gave the outdoor unit five minutes to reset and run the self-diagnostic, and the unit is not on or did not come out of standby mode, it may be time to do a full system reset.

| The system will NOT run: • If the board finds a fault and locks the system. • If system pressure is NOT between 80 and 500 psi. |

To Conduct a System Reset

![]()

Download and keep this full troubleshooting guide for reference later.

If you need additional help with troubleshooting your condenser, watch the video explanation below.